magazine

Spotlight

Posted on

Read

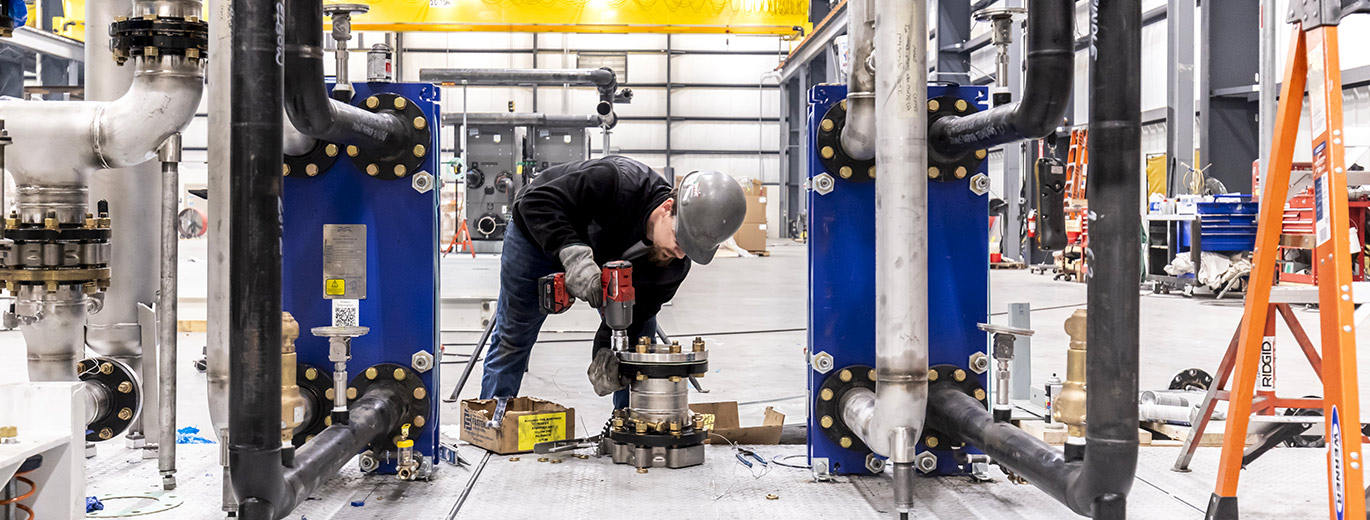

Pioneer spirit

Sully-Miller Contracting Co. has been carrying out major infrastructures projects in California for several years. In 2021, Colas Inc., the parent company of Colas in the United States, created a new entity, Colas Construction USA Inc., to give its American subsidiaries a hand winning more big contracts. We take a tour…